Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

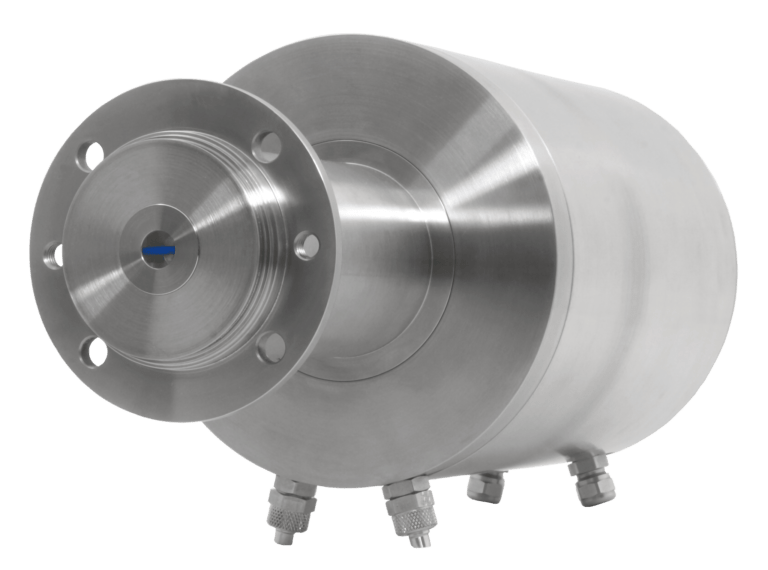

The explosion protection version of the SCHMIDT + HAENSCH process refractometer consists of an intrinsically safe, single-certified sensor, which can be installed in hazardous areas. It is chemical resistant, food safe, and delivers reliable and hygienic measurements, fully in-line with your production process.

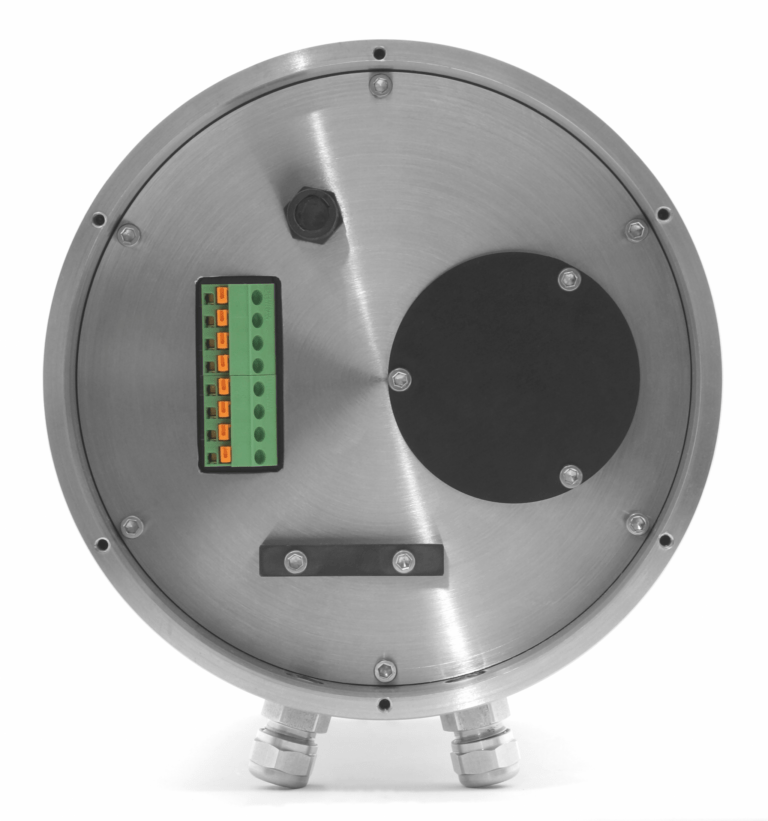

The 7” touch screen is individually configurable. The measured data can be output via Ethernet as a 24 V or 4-20 mA signal, or controllable relay.

For data transmission to other systems, serial RS 232, 485 interfaces, a CAN bus or UPC server are available.

Up to two measuring heads can be connected at the same time.

This fully automatic process sensor is perfectly suited for direct measurement of dissolved solids, process monitoring, and control in hazardous areas. With its explosion protection, it can be employed in the automotive, aviation, petrochemical, and refinery industries.

Conformity: Zone 0 Ex II 1 G Ex ia IIC T4 Ga, ATEX 2014/34/EU, EN 60079-0 (2012) + A11 (2013), EN 60079-11 (2012).

The SCHMIDT + HAENSCH critical-angle refractometer with sapphire prism and high-resolution photodiode array operates consistently, independent of medium color or opacity. Stainless steel measuring head is chemical resistant, food safe, hygienic, for process temperatures up to 120 °C (with connected water cooling) and pressures up to 1 MPa. The measuring signals are routed to the non-explosive area via a special cable (maximum length 500 m) and connected to four Zener barriers. The connection to the central control system is realized with a RTU Modbus or serial RS 485 interface. Alternatively, SCHMIDT + HAENSCH offers a control unit which can also be installed outside the hazardous area.

| Standards | ATEX II 1 G Ex ia IIC T4 Ga IEC in preparation |

| Measuring range | 1.32000 – 1.52000 nD |

| Resolution | 0.00001 nD |

| Precision | ±0.00014 nD |

| Ambient temperature | -20 °C to +65 °C |

| Process Temperature | -20°C to +120 °C* |

| Temperature resolution/precision | 0.01°C / ±0.2°C (0° to 70°C) |

| Process pressure | 0 to 1 MPa (145 psi, 10 bar) |

| Prism | Sapphire |

| Wetted parts | Sapphire (prism), stainless steel, FKM |

| Protection class | IP 67 |

| Light source / wavelength | LED, 589 nm |

| Interface, switches | ModBus, RS485 and 24V with external Zener barriers |

| Dimensions | 330mm x 149mm (length x diameter) |

| Weight | 9600g |

| Operation | One and two measuring headsets are available, connectable with built-in Zener barriers |

| Display | 7″ Touchscreen, 800 x 480 pixel |

| Interface | Ethernet |

| DIN rail parts (expandable) | Switch inputs (24 V) and outputs (24 V / relay / 4-20 mA) / Communication (RS232 / RS485), CAN, UPC Server |

| Highlights | Configuration of measuring head and outputs / Adjust switching thresholds and analog outputs / Concentration and other scales user programmable |

| Power | 85 V … 265 V 50/60Hz |

| Housing | IP65 |

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.