Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

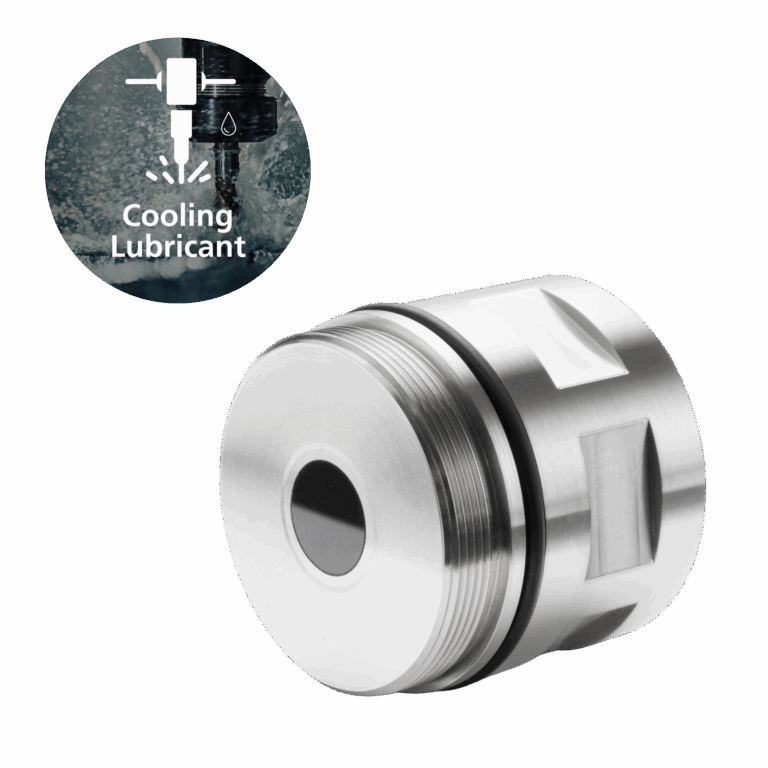

The iCS2 CL inline sensor has been specially developed for the reliable monitoring of cooling lubricants and cutting oils. The fluid concentration sensor continuously and precisely measures the concentration directly in the running process – without any interruption for manual checking of the samples. It therefore makes a decisive contribution to significantly reducing the risk of damage to cutting tools and products. Thanks to its compact design, the sensor can be quickly and easily integrated into existing systems. Even when heavily soiled, the iCS2 CL delivers stable measured values without the need for cleaning. Its exceptional robustness and freedom from maintenance make it the ideal solution for demanding industrial applications. Small and reliable – the iCS2 CL ensures maximum process reliability and consistently high quality when machining various materials with cooling lubricants and cutting oils.

SCHMIDT + HAENSCH has the ultimate solution for you if you are dealing with heavily contaminated liquids, space-limited installations or exposure to ambient light: designed for easy integration into your process control system, it can be connected directly to your PLC via an RS485 Modbus RTU interface. Integrated functions such as temperature measurement and level detection ensure a self-monitoring system. The sensor can also be used to control solenoid valves for direct dosing of cutting oils. Our user-friendly software for data acquisition and configuration of the device is also included in the scope of delivery.

The iCS2 CL sensor has been specially developed for reliable, maintenance-free quality control of the concentration monitoring of cutting oils, lubricating oils and cooling lubricants in space-critical environments. The main purpose of these metalworking fluids is to guarantee optimum cooling and lubrication of cutting tools and polishing machines during the machining of various materials and to prevent damage to the product and cutting tools. Controlling the concentration is therefore important to ensure a high and consistent quality of the parts produced. This is particularly relevant in the electronic, mechanical and optical industries as well as for the automotive and mechanical engineering industries. Its robust design and large measuring surface ensure precise measurement results even under demanding conditions. The sensor is virtually maintenance-free and is fully optimized for use in media containing cooling lubricants. This makes the iCS2 CL the ideal solution for anyone looking for long-term process reliability, minimum operating costs and maximum assurance of product quality – compact in form, powerful in performance.

Refractive Index – RI | Brix (Degree Brix °Bx) | Concentration measurement | Cooling lubricants | Quality and concentration control | Cutting Oil and Lubricant| Oechsle scale

Equipped with a light source at 589 nm, the iCS2 EG sensor sets new standards in the miniaturization of modern process sensor technology – without compromising on measuring accuracy. Its innovative design combines powerful technology in the smallest of spaces: at around the size of a golf ball, the sensor can be easily integrated into almost any system and offers maximum precision for a wide range of applications.

| Measuring scales | Cooling lubricants (CL) Scale |

| Measuring range | 0…20.00 %wt |

| Resolution | 0.1 %wt |

| Accuracy | 0.3 %wt |

| Reproducibility | 0.2 %wt |

| Operating temperature | -10 to + 60 °C |

| Process pressure | max. 4 bar |

| Interface | RS485 Modbus RTU |

| Dimension | 40 mm x Ø 44 mm |

| Weight | 155 g |

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.