Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

The iPR comes with a measuring range of up to 90% Brix (refractive index 1.5200). It is suitable for almost all applications in food production and pharmaceutical industries, but it can also be used for many processes in mechanical and automotive engineering, and in chemical appliances.

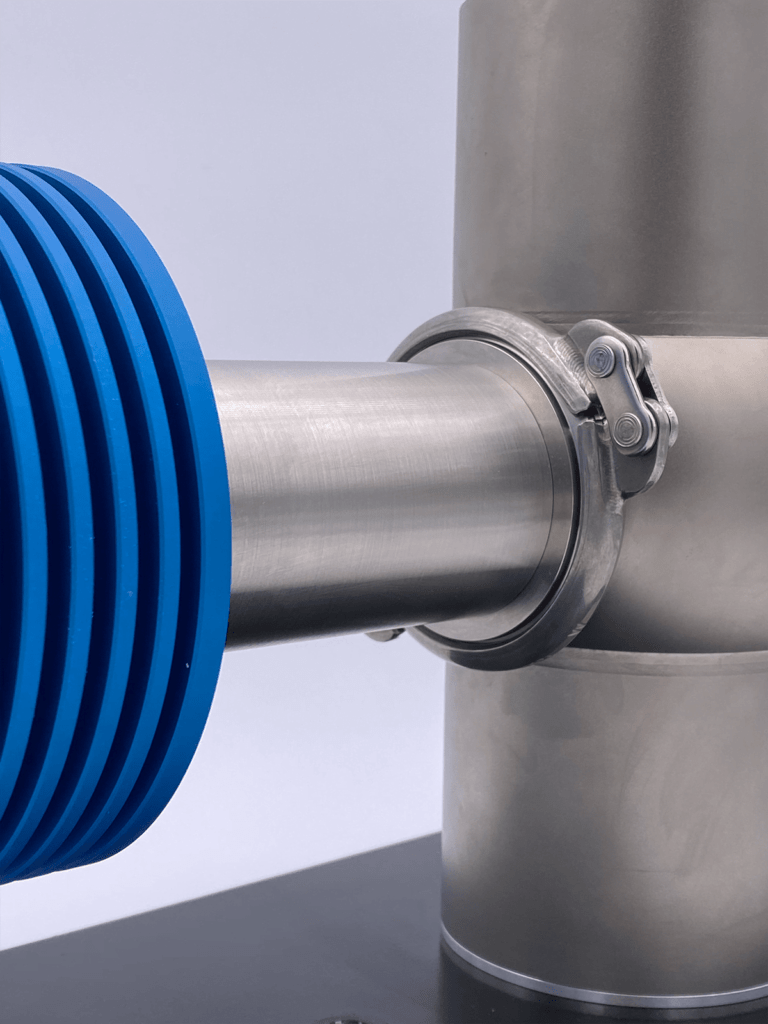

ID-N° 12609 VariVent connection

ID-N° 12612 TriClamp connection

ID-N° 12613 APV connection

The special design and electronic equipment make the iPR highly flexible and easy to use. The iPR-B is equipped with two switch outputs to run, for example, a connected valve (max. 1A, 24 DC) or relay. With this feature is it also possible to control the cleaning of the measuring prism via a magnetic valve.

The iPR-B measuring head can be installed in pipes, reactors, vessels, and mixing tanks, using different weld-in flanges. Our preferred joint system is VariVent. It allows easy installation through a plug-in clamping method. Some processes may require cleaning of the sensor face. SCHMIDT + HAENSCH offers an optional cleaning nozzle or a specially designed ultrasonic cleaning device.

For determination of mixing ratio, the SCHMIDT + HAENSCH Brix refractometer can be applied in the sugar and agricultural industry, in the production of cane and beet sugar, molasses, or in biomass material characterization. These parameters are equally applied for measurements within the food and beverage industry, e.g. production of marmalade, fruit juice, and lemonade and more.

Liquid identification and distinction of materials for interfacing purposes is easily made possible with SCHMIDT + HAENSCH’s iPR-B.

The sophisticated design of the stainless-steel housing of the sensor is equipped with a blue anodized air cooling jacket. This cooling jacket protects the electronic components from overheating in process temperatures up to 90 °C (194 °F). CIP cleaning at the prescribed temperatures is possible when the instrument is switched off.

SCHMIDT + HAENSCH offers customized scales in addition to known standard scales such as Brix, Oechsle, ethylene glycol, sodium chloride, urea, etc.

| User scales | Four scales temperature compensated (e.g. Brix, Oechsel, H2O2) |

| Measuring range refractive index | 1.3200 – 1.5200 RI |

| Resolution refractive index | 0.00001 RI |

| Measuring range Brix | 0 – 90 Brix (automatic temperature correction 10 °C – 50 °C) |

| Resolution Brix | 0.01 Brix |

| Precision refractive index / Brix | +/- 0.00014 RI/ +/- 0.1 Brix |

| Temperature precision | +/- 0.2°C |

| Temperature resolution | +/- 0.01°C |

| Process temperature | – 10 °C to + 90° C |

| Ambient temperature | -10 °C to + 50 °C |

| Process contact material | sapphire; stainless steel, optional: PTFE |

| Max. pressure | 10 bar (1 MPa) |

| Power supply | 24 V DC < 75 mA (20 V – 28 V) |

| Light source | 589 nm LED |

| Analog data output | 2 x 4 – active output

Burden [500 Ω] |

| Digital output | Two digital limit switches (up to 1 A). One serial communication via RS232, RS422 (switchable) or USB |

| Display | As an accessory: can be used next to the iPR or several metres away |

| Software | Configuration program for: serial output, analogue output, monitoring of measured values and saving |

| Process connection | optional: VariVent-Inline (Tuchenhagen) or APV-Inline (APV) |

| Other options | Prism cleaning unit |

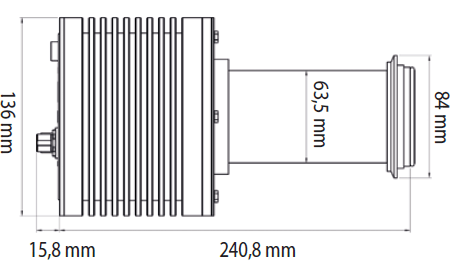

| Dimension | 256.6 mm x 136 mm ( length x diameter) |

| Weight | 3790 g |

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.