Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

SCHMIDT + HAENSCH’s general type process refractometer is made to last. The iPR C2 is an ideal all-round instrument for measuring liquid concentration in a wide range of industrial applications. This compact inline process refractometer performs real time industrial measurements under all conditions for quality control fully in-line with your production process. Automatic temperature compensation for Brix scale is standard; other scales are programmable. The excellent price/performance ratio is an additional reason for the process refractometer’s success.

ID-N° 16266 VariVent connection (more in specifications below)

The iPR C2 is simply and flexibly integrated into your process. With its digital and analog interfaces, it allows for easy, real-time monitoring through your ethernet or WLAN. It delivers continuous measurement and real-time process control with analog and digital outputs, limit comparator, internal diagnostics , and programmable temperature compensation.

SCHMIDT + HAENSCH’s iPRs are virtually maintenance free and will allow for your industrial measurements to be performed hygienically and without loss of product. Measurements are reliable and accurate – no recalibration needed.

The iPR C2 will be reason for your success, maintaining and controlling quality continuously – without manual sample taking or loss of product. Our refractometers enable accurate in-line Brix, total solids, Plato, Oechsle and concentration measurements in hygienic liquid food and beverage processing applications, as well as filling lines and waste control streams.

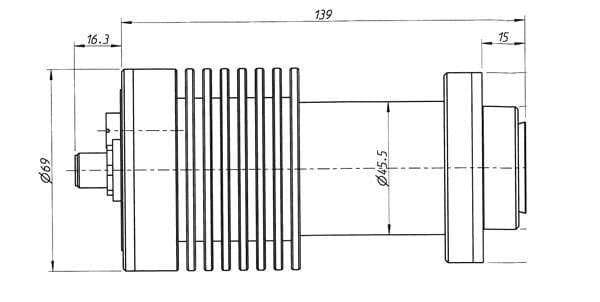

The iPR Compact 2 is the smallest in-line process refractometer we have yet designed. With its uniquely small proportions of only 69 mm x 130 mm, it is particularly fitting for applications that only allow small sizes – whilst maintaining the fit of all communication interfaces. With this device, both 4-20 mA as well as RS232 (or RS 422) exits are covered. Smart engineering with cooling fins and a stainless-steel base make usage possible during high process temperatures (up to 65°C) or with aggressive liquids. As an all-round standard process refractometer, the SCHMIDT + HAENSCH iPR C2 is highly requested in the determination of mixing ratios within a range of industries, including chemical, metal, mining and cooling lubricant monitoring for cooling systems, tooling machinery, and automotive industries. It is also used for food and beverage, quality control, renewable resources, sanitary and household products, semiconductor, and tooling machinery industries.

| Measuring range | 1.3320 – 1.4209 RI |

| Resolution | 0.0001 RI |

| Measuring range Brix | 0 – 50 Brix (automatic temperature correction 10 °C – 50 °C) |

| Resolution Brix | 0.05 Brix |

| Refractive index accuracy / Brix | +/- 0.0002 RI / +/- 0.15 Brix |

| Temperature accuracy | +/- 0.2 °C |

| Temperature resolution | +/- 0.01 °C |

| Process temperature | – 10 °C to + 65 °C |

| Ambient temperature | – 10 °C to + 45 °C |

| Process contact material | YAG; stainless steel, optional: PTFE |

| Max. pressure | 10 bar (1MPa) |

| Power supply | 24 V DC < 75 mQ (20 V – 28 V) |

| Light source | 589 nm LED |

| Analog data output | 4 – 20 mA – active output

Burden [300 Ω] |

| Digital output | Serial communication over RS232,

RS422 (switchable) and USB |

| Display | As an accessory: can be used next to the iPR or several meters away |

| Software | Configuration program for :

serial output, analogue output, monitoring of measured values and saving |

| Process connection | Optional: VariVent-Inline (Tuchenhagen) or APV-Inline (APV) |

| Other options | Prism cleaning unit |

| Dimension | 150 mm x 65 mm (length x diameter) |

| Weight | 1000 g |

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.