Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

This in-line process sensor is especially designed to control the concentration of cutting oils and cooling lubricants in order to reduce the risks of damages on cutting tools and products.

The SCHMIDT + HAENSCH iPS CL delivers high measuring precision in a compact design and opens up a new field of process analysis in particularily tight conditions.

ID-N° 16266

The SCHMIDT + HAENSCH in-line process sensor iPS CL provides a continuous real-time measurement of the concentration and temperature of the cutting fluid.

The instrument can also be used to operate magnetic valves for dosing the cutting oils directly.

The process refractometer is fitted with the Brix scale and the devices can be used without further programming. Software for the data acquisition and the configuration of the device are also included in the scope of delivery.

Because of the fact, that it operates without any moving parts, only maintenance is to change the dry air cartridge.

The quality and concentration of cutting oils and cooling lubricants is important for electronic, mechanical and optical industry, as well as the vehicle- and machine building industry. The main purpose of these oils is to ensure the proper cooling of the cutting and polishing machines and to prevent the damaging of the product and cutting tools. The control of lubricant oil concentration is important to ensure good and constant quality of the produced parts.

The iPS CL measuring range is specifically programmed to cutting oils and cooling lubricants and can therefore help you save costs and time. It’s precise, reliable and fast measuring method helps you to ensure the highest product quality and signficantly reduces damages on cutting tools.

The instrument can operate in closed rooms and also outside in almost all climatic circumstances.

Thanks to its new design it requires fewer parts, resulting in a highly efficient and compact construction. As a true sensor, it can be used in applications which can not be met by conventional refractometers. If you are dealing with minimal volumes, space-limited installations or mobile operation, SCHMIDT + HAENSCH has another ultimate solution for you here. Designed to be easily integrated into your process controls, it can be connected directly to your PLC via Modbus or RS-232 interface.

Integrated functions such as temperature measurement, cleanliness control and filling level detection ensure a self-monitoring system. For an installation in a tank it is recommended to place the refractometer close to a stirrer to assure a high liquid flow and a representative measuring.

| Measuring scales | Refractive Index (RI), Brix (Bx) |

| Measuring range | 0 – 25 𝐵𝑟𝑖𝑥 (Automatic Temperature-correction 5°𝐶 − 45°𝐶) |

| Resolution | 0.0001 RI / 0.1 Bx |

| Precision | ± 0,3𝐵𝑟𝑖𝑥 |

| Temperature accuracy | ± 0,5°𝐶 |

| Temperature resolution | ± 0,1°𝐶 |

| Process temperature | +5°C to + 35°C |

| Ambient temperature | +10°𝐶 to +40°𝐶 |

| Max pressure | 6 bar 10 bar <12 h |

| Power supply | 24V DC < 75mA (20V – 28V) |

| Light source | 589 𝑛𝑚 LED |

| IP class | IP67 |

| Process pressure (max.) | 100 kPa (14,5 psi, 1 bar), max. 4 bar |

| Analog data output | 4−20 𝑚𝐴 – active output 300Ω, 2mA output if outside measuring

ranges or error condition |

| Process connection | optional: VariVent-inline or APV-inline |

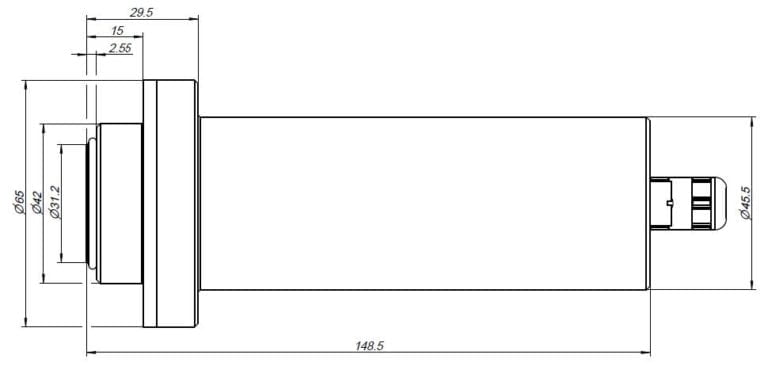

| Dimensions

Weight |

165 mm x 45 mm ( length x diameter)

500 g |

For optional cleaning units as accessories, please contact SCHMIDT + HAENSCH

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.